The Traffic Accident Reconstruction Origin -Article-

The Traffic Accident Reconstruction Origin -Article-

|

|

Introduction:

Imagine you are standing on a tennis court smashing tennis balls

as hard as you can into a wall. Just a few feet in front of the wall

is a net. You strike a tennis ball as hard as you can. It

crushes into the wall and then bounces back to you. You drive

the tennis ball again, but this time it goes into the net and

slows until it loses all its forward velocity. The net cords

stretched out and arrested the speed of the tennis ball.

The time the tennis ball was interacting with the net was much

longer than the time it took to bounce off the wall.

In a severe collision, the occupant is like the tennis ball. The

occupant can either strike the dashboard, which is analogous to

the tennis ball hitting the wall, or strike the seat belt which is

like the tennis ball hitting the net. How much trauma the body

of the occupant experiences will depend on the time period

over which the force is applied and the stiffness of the body parts

absorbing the force. Is it going to be applied

quickly, or a longer period of time? To reduce the peak force,

the occupant needs the force to be applied over a longest period of time possible.

Stretching the time epoch of the collision for the

occupants and redistributing the crash forces to the stiffest

parts of the human anatomy is the duty of the seat belt. Equally

important, seat belts are the best way to prevent ejection from

the vehicle.

Brief History of Seat Belts:

1903 A patent for a sophisticated system of seat belts and upper torso restraint integrated

into a seat back was obtained by a French automobile manufacturer.

1910 A seat strap was introduced to airplanes, mainly to keep the pilot strapped to

the plane in cases of inverted flying.

1949 Production installed seat belts are offered as an option.

1966 Congress required lap belts (pelvic restraints) for front seat outboard and rear seat outboard

positions.

1967 Congress adopted Federal Motor Vehicle Safety Standards (FMVSS) 208, 209, and 210 dealing with

restraint systems.

1968 Congress requires lap/shoulder belt combinations for all vehicles sold.

1971 FMVSS 208 was amended to specify occupant crash protection and establish a criterion for occupant

crash injury.

1972 Seat belts became mandatory.

1973 The shoulder belt becomes permanently attached to the lap belt.

1974 Ignition interlock systems were required that would not allow the vehicle to be started

unless the seat belt was in use. Requirement rescinded one year later.

1977 Airbags are to be phased in by car size.

1981 Airbag requirement is rescinded.

1987 The passive restraint systems are required with a phase-in.

1993 Mandatory phase-in of dual airbags.

Seat Belt System:

The seat belt restraint system contains some or all of these

components;

1 - shoulder guide loop,

2 - webbing,

3 - non-locking retractor,

3a - retractors (generally),

4 - automatic locking retractor,

5 - emergency locking retractor,

6 - vehicle sensitive retractors,

7 - webbing sensitive retractors,

8 - three point belts,

9 - upper torso webbing,

10 - pelvic webbing,

11 - buckle,

12 - buckle release,

13 - tongue (latch plate),

14 - selvage,

15 - anchorages,

16 - mouse (carrier and track),

17 - adjustment hardware.

Components and Usage:

(1) The shoulder guide loop, often spoken of as the "d" ring, is

the oval guide that the webbing travels through between the

retractor and the buckle. Typically attached to the 'B' pillar,

or roof line, the shoulder guide loop is often made of metal with

a plastic coating, or completely of a plastic. During collisions

with speed changes greater than about 12 mph, the rapid pay out

of webbing sliding through this ring can burn and abrade the

nylon covering and leave telltale marks of usage of the belt.

(1) The shoulder guide loop, often spoken of as the "d" ring, is

the oval guide that the webbing travels through between the

retractor and the buckle. Typically attached to the 'B' pillar,

or roof line, the shoulder guide loop is often made of metal with

a plastic coating, or completely of a plastic. During collisions

with speed changes greater than about 12 mph, the rapid pay out

of webbing sliding through this ring can burn and abrade the

nylon covering and leave telltale marks of usage of the belt.

(2) The webbing is a narrow fabric woven with continuous filling

yarn and finished with selvages. During a significant collision,

great enough frictional forces can be generated to melt nylon

material from the d-ring onto the webbing, skin can also be

abraded or melted onto the webbing.

(2) The webbing is a narrow fabric woven with continuous filling

yarn and finished with selvages. During a significant collision,

great enough frictional forces can be generated to melt nylon

material from the d-ring onto the webbing, skin can also be

abraded or melted onto the webbing.

The belt (now typically a polyester weave with less elastic

property but higher tensile loading capabilities) length and a

coating of foreign materials like dirt or blood can also be

indications of usage. The federal law mandates the width of the

webbing to be not less than 1.8 inches except those portions that

do not come into contact with the 95 percentile test dummy.

(3) The non-locking retractor allows the webbing to be spooled

out at any time without locking and stopping this from happening.

This is an older form of the retractor

(the original form) and

the occupant was responsible for adjusting the webbing length

once the belt was buckled. The retractor would spool in excess

webbing for stowage inside the retractor housing.

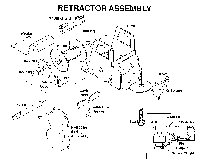

(3a) The retractor itself consists of various components (see illustration to

left). The primary parts are the

frame, which houses

the mechanism; the spool, which winds the webbing up; the ratchet

is located on the sides of the spool and are a portion of the

mechanism to stop the spool-out; the spring assembly which acts

to put tension on the spool to allow it to draw up the webbing;

the lock pawl (A4) is a bar that is forced into position across

the teeth of the ratchets; the G-sensor is an inertial device

that when free to move, releases or applies a force to a spring

which moves the lock pawl or allows the lock pawl to move into

position across the ratchets. For comfort, to maintain a certain

length, a ratchet lever will engage with the teeth of the

ratchet.

Also, in webbing sensitive mechanisms, pins on the side of the

ratchet stick out. Inertial bars, attached to light springs and

mounted to the outer sides of the spool hub, spin freely under

normal rotations. Under rapid rotation, with a sudden spool out

the inertia of the bars pull them outward elongating the spring

and causing the bars to quickly engage with the pins and lock the

retractor. Some design have multiple retractors, often in door

mounted passive/active systems.

(4) The automatic locking retractor allows the webbing to be with

drawn and then rewound but will not permit a second withdrawal

until the belt is nearly completely rewound. This device allowed

for the installation of a locking device within the mechanism

located inside the retractor housing. The mechanism was

typically a clutch and locking bar combination which would engage

if the belt spooled up an amount when it was in use.

(5) The emergency locking retractor allows the belt to spool out

and rewind freely except when a vehicle acceleration demands it

locks up. The mechanism may be of an inertial reel nature or

vehicle sensitive type.

(6) The vehicle sensitive retractors act similar to the emergency

locking retractors when the vehicle tilts at greater than a 15-degree pitch (0.26 G) or decelerates at greater than or equal to

0.7 G in ANY direction. This system allows for less spool out of

the webbing.

The mechanism for the lock up is a pendulum or other inertial

device which resists the acceleration of impact and causes a

bar to lock across the ratchets of the retractor. The

pendulum hangs freely and moves slightly in relation to the frame with changes in

acceleration. An accelerations of more than 0.7 G is great enough to

overcome the inertial force and swing the pendulum fully which,

in turn activates the locking bar or pawl which stops the motion

of the teeth of the retractor ending spool out. Another form of

the inertial device is a steel ball which moves under a

sufficiently large acceleration and causes the engagement of the

lock pawl or a clutch which stops the spool out.

The distance of travel between the pawl and the teeth are less

than or equal to 1/10 of one inch. The lock up force is along

the order of 0.3 G to 0.5 G, and occurs in about 15 ms to 30 ms

(0.015 - 0.030 seconds), but may be as rapid as 9 ms. At the

first lock up the reel will engage and halt the pay out of

webbing and then, with rebound into the seat the spring tension

on the reel will wind up any additional slack created.

Older models of the pendulum were free to drop through a hole in

the roof of the G-sensor housing if the vehicle over turned and

thus, releases the ratchet allowing free spool out of the

webbing. Newer devices have a ring which denies the pendulum

from dropping through the top plate of the G-sensor housing

should the vehicle overturn and prevents the pawl from

disengaging.

(7) Webbing sensitive retractors automatically lock when the

webbing is suddenly withdrawn, they do NOT lock when the webbing

is slowly spooled out. The mechanism of lock up was a mass

attached to a light spring. When the retractor began to rapidly

spin with sudden pay-out, the mass would lock up the spool and

prevent further withdrawal of the webbing from the spool hub.

(8) Three point restraints are seen in many vehicles today, the

pelvic webbing and torso webbing are sewn together at the buckle

area to maintain one triangular shaped belt. One end may be

fixed to the vehicle near the door sill without a retractor or

both pelvic and torso webbing may operate with separate

retractors (often seen in the door mounted systems).

(8) Three point restraints are seen in many vehicles today, the

pelvic webbing and torso webbing are sewn together at the buckle

area to maintain one triangular shaped belt. One end may be

fixed to the vehicle near the door sill without a retractor or

both pelvic and torso webbing may operate with separate

retractors (often seen in the door mounted systems).

A continuous loop belt is a one retractor system. Typically, a

floor anchor is used for the buckle and one portion (the distal

end of the pelvic webbing)of the loop. The torso webbing feeds

up from the retractor through a guide loop typically mounted on

the 'B' pillar and the latch plate slides on the webbing via a

guide loop. Movement of the latch plate may be limited by a

button or build up of material sewn onto the webbing.

(9) The upper torso webbing (shoulder belt or shoulder strap) may

be a part of a continuous belt or may be separately attached to a

motorized mouse that runs along a track. The upper torso belt

typically spools from a retractor and locks into a buckle with/or

as part of a separate system with the lap belt.

(10) The pelvic webbing or lap belt may be part of a continuous

system or may be separate in the case of some active/passive

design systems. It runs from a retractor to a buckle that it

latches into, often in conjunction with the torso webbing.

(11) The buckle is the one piece housing that surrounds the

release and may extend up from the floor mounted anchorage. The

system is functioning or "buckled" when the latch plate has

clicked home into the receiving portion of the buckle.

(12) The release is the button in the portion of the buckle

housing that allows the tongue to disengage from the buckle

receiver. The release is designed to minimize unintended

activity and should not release with a force less than or equal

to 30 pounds.

Releases may be on an end or located near the center of the

buckle.

(13) The tongue is the metal plate that is surrounded by, but

extends from the conjunction of the webbing or may slide somewhat

freely on the continuous loop webbing. Typically the tongue

(latch plate) has a slot in it for engaging with the receiving

end of the buckle mechanism. The latch plate often has its own

guide loop which may be constructed from metal or plastic.

(14) The selvages are the woven edges of the webbing.

(15) Anchorages are technically defined as "attachment hardware"

and must be manufactured to meet certain loading requirements.

(16) Mouse. (Carrier and track assembly). The mouse is a small

motorized unit that attaches the distal end of the upper torso

restraint for those types of passive systems that use this

mechanism. When the door is opened, the mouse runs forward on a

track along the head liner or sill and when the door is closed,

the mouse runs rearward positioning the torso belt in place. The

upper torso restraint is sometimes anchored to the floor with its

own buckle. A buckle and emergency release is designed into the

mouse in that device. Some systems employ separate buckles for

the upper torso (passive) and the pelvic (active) webbing.

(16) Mouse. (Carrier and track assembly). The mouse is a small

motorized unit that attaches the distal end of the upper torso

restraint for those types of passive systems that use this

mechanism. When the door is opened, the mouse runs forward on a

track along the head liner or sill and when the door is closed,

the mouse runs rearward positioning the torso belt in place. The

upper torso restraint is sometimes anchored to the floor with its

own buckle. A buckle and emergency release is designed into the

mouse in that device. Some systems employ separate buckles for

the upper torso (passive) and the pelvic (active) webbing.

(17) Adjustment hardware. This type of hardware is designed to

fit the belts to the individual user and includes the buckle,

attachment hardware and the retractor.

Load Limiters:

Load limiters are simple mechanisms to increase the ride-down

time of the event for the occupant while staying below the limits

of torso over load. Systems manage the energy by deforming at

the anchorage or the use of a metal honeycomb covering that

deforms prior to the onset of extreme tensile loading on the

webbing.

Load limiters are simple mechanisms to increase the ride-down

time of the event for the occupant while staying below the limits

of torso over load. Systems manage the energy by deforming at

the anchorage or the use of a metal honeycomb covering that

deforms prior to the onset of extreme tensile loading on the

webbing.

Energy management loops are a series of webbing folds, located

near the anchorage, sewn together accordion fashion. As the

tensile loading on the webbing approaches a limit (typically less

than 1,500 lbf - which has been shown may cause serious chest

injuries) the stitches break releasing some of the folds and

absorbing additional kinetic energy through the webbing.

Slack:

Most manufacturers report that having in excess of 1.5 inches of

slack in the belt will create excessive webbing and will allow

for too great a payout of the belt, increasing the travel

distance (excursion) of the occupant.

Pre-tensioners:

Excessive slack may be accumulated due to bulky clothing or

manipulation of the webbing for comfort. The purpose of the pre-tensioner is to take up excess webbing that has spooled out

immediately before the collision forces act on the occupant (15

ms - 30 ms). This allows for a tighter couple between the

car/restraint and occupant system and reduces the length of the

travel for the occupant with a better apportioning of the

collision forces.

One system also works with a cable and pulley system affixed to

the engine that tugs the cable and tightens the webbing as the

engine of the car is moved rearward, or more commonly it may

operate on a sensor and explosive charge that fires a short bolt

that takes the slack out of the webbing.

Inertial devices also are employed as pre-tensioners and

grabbers. Grabbers grip the webbing and stop the spool out of

webbing slack that is not tightly spooled around the hub.

Typically, pre-tensioners and grabbers work in the 12-mph delta v

range and may remove as much as six inches of slack from the

system. The pre-tensioner typically operates in the range of 17

ms (0.017 seconds) and may activate prior to the airbag beginning

to deploy.

Explosive pre-tensioners DO NOT WORK if the seat belt is not

buckled.

Types of seat belts:

Type 1: A lap belt only for pelvic restraint.

Type 2: Is a combination of pelvic and upper torso restraint.

Type 2A: A separate shoulder belt intended to be used in conjunction with a lap belt to form a type 2 assembly.

Passive restraints: The type of restraint that requires NO action

on the part of the occupant to put the device in place. Passive

restraints were designed to increase the lack of compliance with

seat belt usage.

Active restraint: The occupant is required to take some action to

ensure the restraint is worn.

Passive/Active: There are combinations that have a passive torso

restraint and an active pelvic restraint.

Pay-Out or Spool Out:

This is the webbing length that is created by the loosely wrapped

webbing around the spool hub having the slack removed, as well as

the amount that is pulled from the retractor prior to its

locking.

FMVSS 208 - Occupant Crash Protection:

Passenger cars manufactured since 1972 have been required to meet

specifications for crash protection at certain locations in the

car. The manufacturer could comply with these demands in three

ways:

(1) First Option: - Complete Passive Protection. The vehicle shall meet crash protection requirements

as set forth by means that require no action by vehicle occupants (passive restraints).

(2) Second Option: -Lap Belt Protection System With Belt Warning. Have a type 1 or type 2 belt (with a

detachable shoulder portion) at designated seating positions with a warning (audible or visible to driver)

device.

(3) Third option: - Lap and Shoulder Belt Protection With Belt Warning. Standards similar to the

second option.

More recently the standard has shifted to primarily passive

systems.

Crash protection:

The standards set forth these criteria: The vehicle, at any speed

up to and including 30 mph, is crashed into a fixed barrier that

is perpendicular to the line of travel of the vehicle, or at any

angle up to 30o; the instrumented test dummy must not show

accelerations, or loading of specific areas, higher than set

forth in FMVSS 209; no part of the system may fail.

Side Impact:

A barrier weighing 4,000 lbs. with a vertical, rigid, flat,

rectangular surface, 6.5 feet wide by 5.0 feet high, is

accelerated in a straight line and crashed into the side of the

car. The barrier cannot undergo any significant static or dynamic

deformation and absorb no significant portion of the energy

resulting from the impact, save rebound velocity.

Injury Criteria:

( A ) The anthropometric test dummies shall be completely

contained during the test.

( B ) The dummy shall not record a resultant head acceleration

such that the equation:

shall exceed 1,000, where a is the resultant acceleration

expressed as a multiple of the acceleration of gravity (g) and t1

and t2 are any two points in time during the crash of the vehicle

which are separated by not more than a 36-ms time interval (0.036

seconds).

( C ) The resultant acceleration of the c.g. of the upper thorax

shall not exceed 60 G's, except for intervals whose cumulative

duration is not more than 3 ms.

( D ) The compressive force transmitted axially through each

upper leg shall not exceed 2,250 lbs.

FMVSS 209 - Seat belt assembly requirements:

Webbing breaking strength:

6,000 lbf Type 1

5,000 lbf Type 2, 2a - pelvic*

4,000 lbf Type 2, 2a - shoulder*

(* together)

Elongation percentage belt type load

20% Type 1 2500 lbf

30% Type 2 2500 lbf - pelvic

40% Type 2 2500 lbf - torso

Emergency Locking Retractor:

Shall lock before webbing extends one inch when the retractor is

subject to a deceleration 0.7 G. Shall NOT lock before the

webbing extends more than two inches when the retractor is

subject to a deceleration of 0.3 G.

Attachment hardware:

Anchorages and all hardware must be able to withstand the same

loading as the webbing. The performance of the system shall not

fail at 20 G. The hardware must withstand a force of 9,000

lbs. except that in which the ends of two or more assemblies

cannot be attached to the vehicle by a single bolt shall have a

breaking strength of not less than 5,000 lb. Hardware designed

to receive the ends of the two seat belt assemblies shall

withstand a tensile force of at least 6,000 lbs.

Buckle Release:

The buckle of a type 1 or type 2 seat belt shall release when a

force of not more than 30 lbs. is applied.

Buckle:

The buckle of a type 1 or type 2 seat belt assembly shall NOT

release under a compressive force of 400 lbs. Metal to metal

buckles when in PARTIAL engagement shall separate by a force of

not more than 5 lbs.

Structural Components:

Type 1: The assembly loop shall withstand a force of not less

than 5,000 lbs., and each component shall withstand a force of

not less than 2,500 lbs. The loop shall not extend more than 7

inches when a force of 5,000 lbs. is applied. The length of the

assembly between anchorages shall not increase more than 14

inches under a force of 5,000 lbs. Any webbing cut by hardware

shall have a breaking strength at the cut of not less than 4,200

lbs. Complete fracture of any solid section of metal attachment

shall not occur during the test.

Type 2: The structural components of the pelvic restraint shall

withstand a force of not less than 2,500 lbs. The structural

components of the upper torso restraint shall withstand a force

of not less than 1,500 lbs. The structural components of the

assembly that are common to the pelvic and the upper torso shall

withstand a force of not less than 3,000 lbs. The length of the

pelvic restraint between anchorages shall not increase more than

20 inches when subjected to a force of 2,500 lbs.

The length of the upper torso restraint between anchorages shall not increase more than 20 inches when subjected to a force of 1,500 lbs. Any webbing cut by hardware during the test shall have a breaking strength of not less than 3,500 lbs. for the pelvic webbing and not less than 2,800 lbs. for the upper torso webbing. No complete fracture through any solid section of metal attachment hardware is allowed.

FMVSS 210:

Seat belt anchorages, attachments, hardware and attachment bolts

must withstand a 5,000 lb. force. Type 1 and type 2 seat belt

anchorages must withstand a 5,000 lbf load for 10 seconds. The

load is applied at an onset rate of not more than 50,000 pounds

per second, and attaining the 5,000 lbf load in not more than 30

seconds. Type 2 (automatic) seat belt anchorages must withstand

a 3,000 lbs. for 10 seconds when that load is applied with an

onset rate of not more than 30,000 lb/second, and attaining the

3,000 lbf load in not more than 30 seconds. The load for each

test must be applied in the direction in which the seat faces to

a pelvic block, at an angle of not less than 5 degrees or more

than 15 degrees.

Mandatory Usage Laws:

Mandatory use laws immediately increased compliance in many areas

by about 15% of the driving population, but passive restraints

alone tend to receive nearly 80% compliance.

Primary Direction of Force:

The PDOF is a physical property imparted to an object during the

impulse as a result of being involved in a collision. The normal

and tangential forces at a contact area combine to yield a single

resultant force at their peak or limit, often spoken of as

maximum engagement. This force, imparted by a component of the

momentum change of each car (which is relative to the mass of the

effected vehicle) can be thought of as acting in a single

direction. The occupants will "appear" to move opposite of the

PDOF when, in reality, the vehicle is suddenly accelerated in the

direction of the PDOF and the inertia of the occupants causes the

car to move toward them.

Delta v:

By definition:

Delta v, means generally a change of velocity, the term has a

specific meaning in the accident reconstruction community. It is

identified as the instantaneous change in speed that occurs

during the momentum exchange at Impulse (F dt).

As the definition of acceleration (above) indicates, the instantaneous change in the magnitude and direction of the velocity is equivalent to the instantaneous change in the magnitude and direction of the acceleration during the time period of the momentum exchange. This change in velocity has been shown to be a good indicator of the level of injury an occupant may receive.

Conclusion

This introductory paper has covered basic seat belt nomenclature. Types of seat belt systems and how they function were also presented. Finally some basic theory was discussed. In the next installment a general method for examining and testing restraint systems will be developed.

Sources:

SAE TOPTECH - Passive Restraints

SAE 840396 - Diagnosis of Seat Belt Usage in Accidents.

SAE 840392 - Historical Perspective on Seat Belt Restraint Systems

NHTSA - FMVSS 208, 209, 210

Texas A & M - Biomechanics Course

Biomechanics of Trauma, by Nahum and Melvin

CHP Academy - lecture notes from TAR

The position provides on-scene documentation through total station survey and photography of traffic collisions involving severe injuries and death. The entire County population is over 3 million residents, and the County maintains over 1,800 miles of roadways. Mr. Phillips has investigated hundreds of fatal collisions during his time with the County. He is used as a consultant for allied agencies, County Counsel and the District Attorneys' Office.

Mr. Phillips has consulted with Law Firms through out the western United States as well as the State Attorney Generals Office and the Department of Transportation.

Mr. Phillips holds Bachelor Degrees in Criminal Justice and Engineering (Manufacturing) and has attended many hundreds of hours of specific technical training in the field of collision reconstruction.

He can be contacted at [email protected]

|

Copyright ©

|